Overcome Irregularity

Let the robot worry about part tolerances, or simply reduce the costs for specialised jigs. In-line part recognition and measuring allow for an adaptation of the robot’s paths – fitted precisely on the part – within the running process.

Part tolerances, uncertain environments, or the necessity for complex jigs often represent a barrier for automatization. Integrating sensor feedback with robust and adaptive control strategies can open up new fields for robotic applications, for example, large scale fabrication, where the final product, or the part to be processed is larger than the robotic system applied. But, also, manufacturing tasks, where workpiece tolerances influence processing precision, can only be realised applying adaptive process strategies. In addition, an intelligent sensing and control strategy can compensate for errors and imprecision of the robotic system itself and increase absolute robot positioning accuracy.

Research and Development

Innovative approaches to robotics and sensing allow for automation processes to enter new domains.

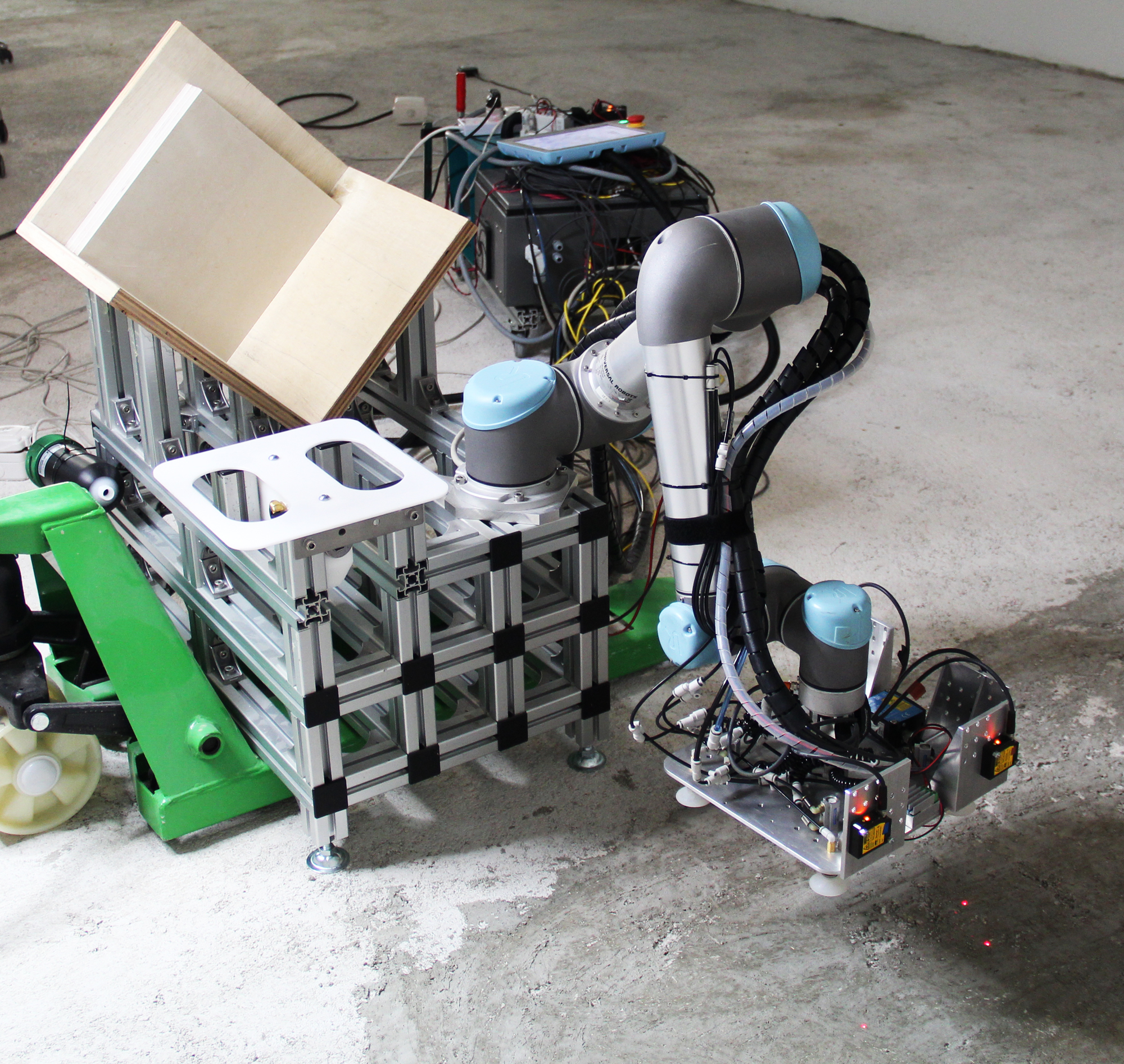

Mobile Robotic Tiling

Adapting to material tolerances and an uncertain environment of a construction site are key aspects in the research and development of a mobile tiling machine. These challenges are met through integrating specific perception and localisation strategies into the robotic control. The research is conducted in collaboration with Gramazio Kohler Research and the Singapore ETH Centre.

Watch the first Prototype in Action

Interested in Adaptive Processing?

Feel free to contact us.

Adaptive processing could be a solution for you, if you want to reduce the need for specialised jigs, have to deal with uncertainties, achieve high accuracy with robotic tooling, or simply want to increase process reliability.