ROB Technologies develops software solutions that empower our clients to adapt their robotic processes easily and quickly to new production tasks, regardless of any programming knowledge.

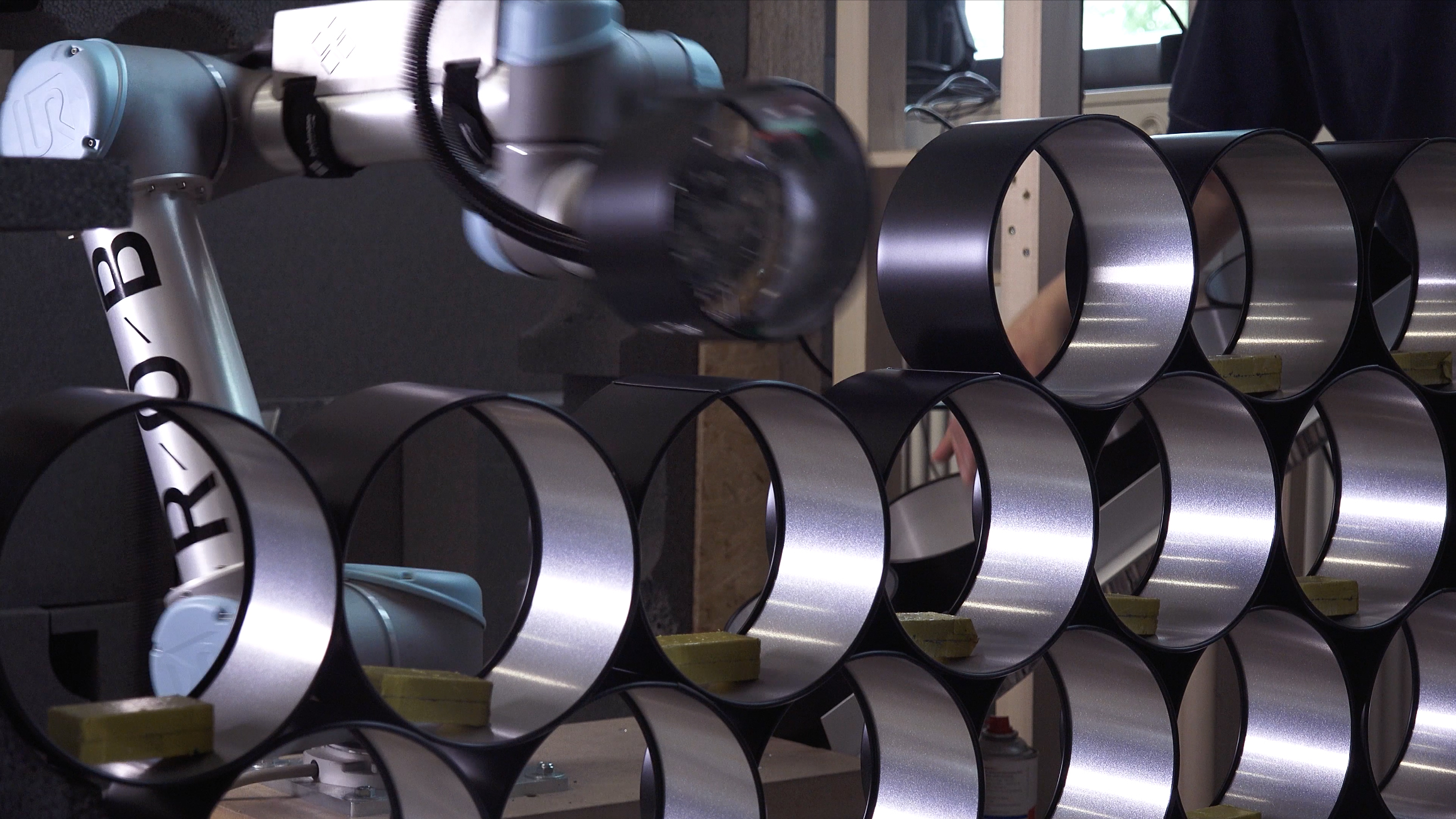

Through facilitating the automated production of unique parts and small batch sizes we open new contexts for robotic use, especially, for small and medium sized manufacturers.

Our technology can be applied to a wide range of fabrication scales. Solutions encompass not only the deburring and chamfering of parts and application of gluing paths, but also large scale robotic construction, such as the assembly of individual timber wall modules or the robotic assembly of non-standard brick façade elements.

Software

Synchronising design and fabrication.

Solutions

Enabling flexible robotic fabrication processes.

Introducing WoodFlex 56

The WoodFlex 56 multi-functional gantry robot is specialised on the automated assembly and processing of timber constructions. ROB Technology developed and implemented the complete control software, featuring an immediate connection between the shop drawings and the robotic control.

See the WoodFlex 56 in action at Erne AG Holzbau

Who we are

ROB Technologies’ mission is to enable an efficient operation of robotic systems in the field of non-standard individual fabrication of high-quality products.

A Spin-off Company of ETH Zurich, ROB Technologies draws on a decade's research on synchronising advanced digital design with robotic automation processes.